The Model scale 1/35°

The model of U-47 is with ballast, for static or dynamic, and radiocontrolled diving.

1°) Building

1-1°) What the kit is made of:

* 1 hull polyester 1, 92m,

* 1 higher brass 8/10 bridge precut in 3 parts (according to plans of the kriegsmarine),

* 1 standard coning tower VII B with cut out brass floor,

* 1 set of upperworks.

1-2°) The assembly:

The installation of the bars of diving, the rudders and the propeller shafts is done without too many difficulties, as on the majority of the sailing models. The skittle strongly should be leaded, with approximately 6 kilos of lead.

Adjustment of the interior of the hull.

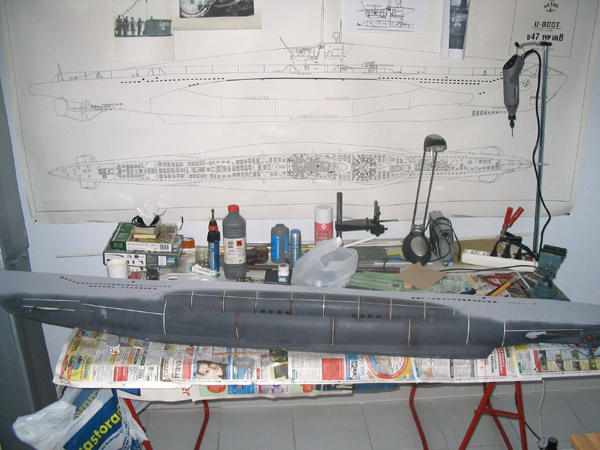

We do not see large-thing, it is a little bazaar on my bench, but other more precise photographs will arrive soon!

1-3°) The ballast:

It is the principle of glass turned over in a sink full of water, which fills only if we make a hole above...

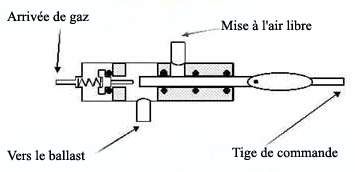

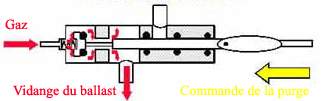

In the model, it is a PVC tube stopped at the ends, perfectly tight. A hole of admission and drainage of water is bored below. Above, a " three ways " valve allows a setting in the open air of the ballast to admit water, and thus to weigh down the model to make it diving; conversely, it also makes it possible to admit gas coming from a bottle under pressure, in order to drive out the water of the ballast, and thus to make raise the submarine.

|

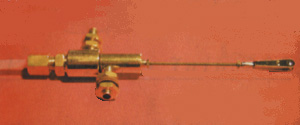

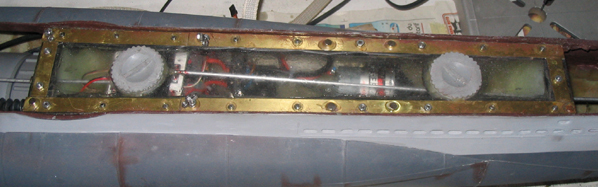

The drawer valve

is controlled by a stem connected to a servo unit. |

|

Valve

in neutral position: the ballast does not fill,

nor is emptied: the submarine is balanced. |

|

The servo order

filling of the ballast: the air

contained in this one is evacuated, replaced by water, there penetrating

by the hole under this one. |

|

The servo order the water draining of the ballast; the gas exerts a pressure on the top of this one, which is evacuated by the hole under the ballast. |

2°)Sealing

2-1°) Guiding principle:

My preceding submarine, U-995, had a single tight hull inside. It is what caused its loss. The great volume of this tight hull did not authorize any flees, that it is of water or gas of the lead-acid battery (see the page concerning these facts). For U-47, the idea is to only seal off what needs some, and to flood the remainder of the hull.

2-2°) Manufacture of a tight compartment:

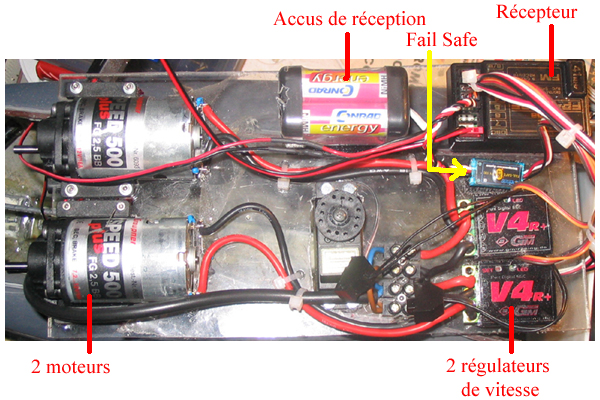

A tight part contains the engines, the receiver,

the two speed regulators, the accumulators of reception, the servo for the

rudders,

the servo for the elevators back, the servo for the drawer valve of the ballast

and the system " fail safe ".

In the following table, I detail the stages of manufacture of this tight part:

|

For those which

knew the old version of U-47, I dismounted the tubes

containing the engine room, the receiver and the servos. |

|

The hull is empty,

it is there that will come the tight compartment.

|

|

The hull is turned

over, the holes of drainage of water must be

stopped. |

|

Two partitions

should be cut out, make in plexyglass 3mm.

|

|

Coarse cutting

is refined with the polishing machine.

|

|

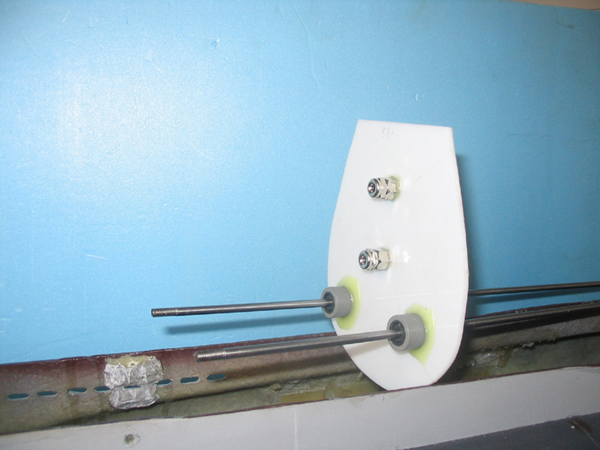

It is necessary

to install pass-partition tight for the orders of the

servos, and two ball bearings with lip seals for the propeller shafts. |

|

Front views, two

partitions with the passages of orders the servo one

and propeller shafts. |

|

The propeller shafts

are tight thanks to the lip seals.

|

|

The back partition

is attached to the Araldite, then sealed off with For the front partition, it is similar! |

|

- 2 electric engines Speed 500 reducted 2.33, - 2 speed regulators, - 1 Robbe receiver for radio operator F-14 NAVY, - 1 pack of accumulators 4,8V, - 1 Fail Safe CONRAD. |

|

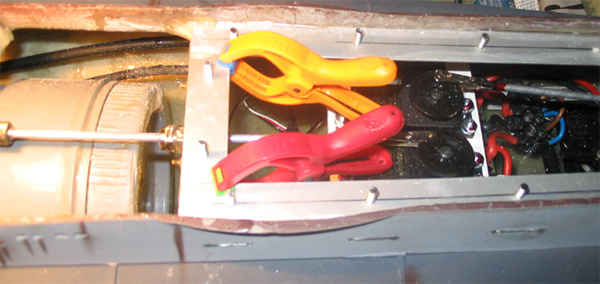

The turntable equipped

is assembled in the tight compartment. Now it

is necessary to make him a lid, which will be fixed on a framework in profiled aluminium. |

|

The aluminium framework

is finished, fixed well at the hull and the One distinguishes platinizes it equipped and the servos. |

|

A rubber seal is

necessary for the sealing of the lid. An end of tire

tube of wheel of truck makes the deal. |

|

The joint is cut

out.

|

|

Tthe engines...

|

|

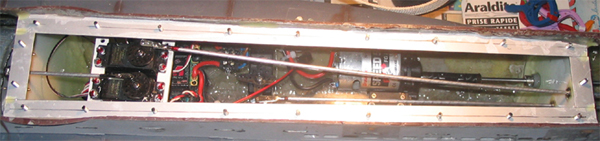

Sight of the back

partition.

|

|

Lid in plexyglass,

fixed by nuts.

|

|

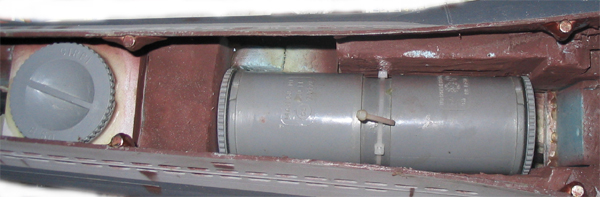

Sight of the ballast

of 2 liters, with the part seals behind.

|

2-3°)The propulsion accumulators:

The lead-acid battery was replaced recently by a pack of NiMh accumulators of 7.2V and 3300 mAh, positioned inside a tube PVC of 50mm of diameter. The risks of hydrogen degasification are, in my opinion, non-existent.

3°) Painting

Two tone of gray are used;

dark gray: Tamiya XF63, and clear gray:Tamiya

XF19

|

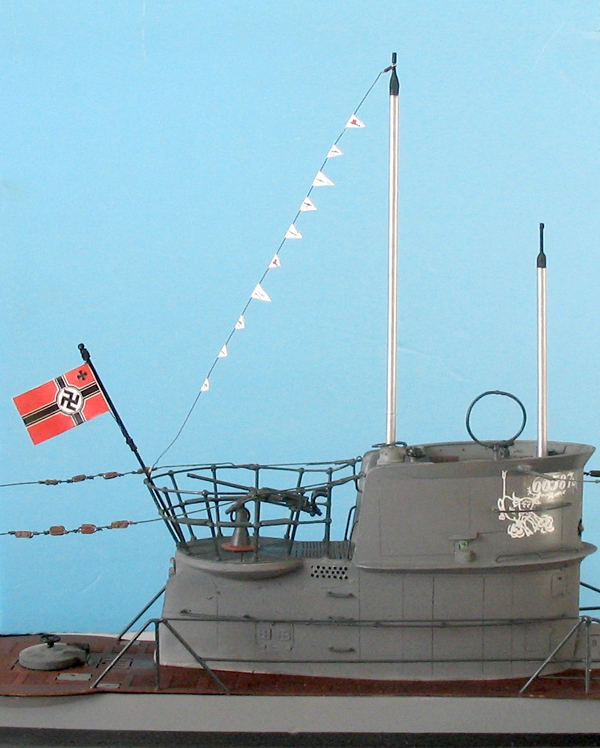

Painting of the

kiosk in clear gray, it is necessary to mask the parts

which are painted of another color. |

|

The result, before

ageing.

|

|

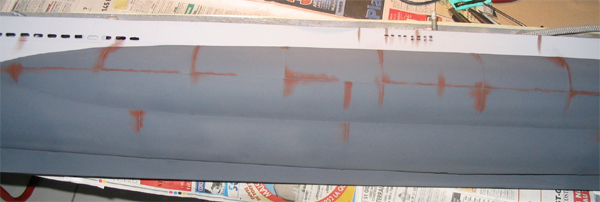

Installation of

strips to give volume to the hull.

|

|

Painting in clear

gray.

|

|

Painting in dark

gray.

|

|

Painting of the

out-of-date poop.

|

|

Painting of the

out-of-date prow.

|

|

Out-of-date painting

of the ballasts.

|